5 Things to Consider When Buying Stretch Film

Understanding the difference between stretch film and shrink film is just the beginning to understanding stretch film’s capabilities in your production line. Here are some points to discuss with your sales representative when determining the best film for your budget and application.

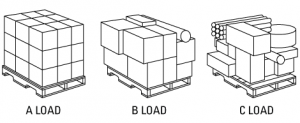

1. Determine the Load Size

Type A Loads: Uniform in shape. The load size closely matches the pallet size. These are obviously the easiest loads to wrap. Few film puncture points exist. This type of load is often seen at manufacturing locations where the same product is prepared for shipment load-after-load.

Type B Loads: Less uniform than type “A” loads. The stacking pattern may be irregular and /or the load size may not match the pallet size. Several film puncture points exist. More film selection judgement is required, especially at high levels of film stretch and /or high film application tension. Type “B” loads appear at smaller manufacturing locations and distribution warehouse locations. Each pallet contains two or three products palletized for a single destination.

Type C Loads: The worst of all to stretch wrap. No two loads are the same. Their size and shape range are all over the place. Sharp points seem to be everywhere and /or there is a major difference between the load and the pallet size. Film selection is critical. Type “C” loads are assembled at the distribution centers who supply retail store locations (i.e. grocery, drug, pet supply, automotive). Each load may contain dozens of different products.

2. Determine the Type of Equipment

Just as is true with any industry, the stretch film industry has gone through some huge changes when it comes to innovation in film manufacturing. Because of these innovations, it is important to make sure your film matches the equipment being used to save on costs.

- Spiral wrap film should generally be used when the loads vary in configuration.

- Fully automatic high speed stretch wrappers equipped with pre-stretch usually require a premium grade of stretch film to make sure the equipment is being fully utilized.

- Economy stretch films can be used for low stretch on conventional equipment.

- A mid-range stretch film is needed for pre-stretch equipment operating at moderate levels.

For instance, if your piece of equipment can only pre-stretch your film 200% at most, you wouldn’t want to spend the extra amount on film that can stretch 400% because you aren’t benefitting from that added innovation. Generally, the film that can stretch 400% is a premium film compared to the film that can only stretch 200% and you pay premium dollar for it. Likewise, if your piece of equipment can pre-stretch your film up to 400% then you want a film that can meet that expectation without breaking – it will save you money per load in the long run.

3. Determine the Type of Product being Unitized

The weight of the pallet load and type of product being wrapped must be considered when selecting film type, gauge and number of wraps. A significantly heavy pallet load will generally need a heavier gauge film than a very light pallet load. For instance compare a pallet of cinder blocks and the impact of the weight of the load during the vibration that occurs in transit vs a pallet of pillows. Although the loads might be the same L x W x H, different films might be necessary to secure the load efficiently at the lowest cost possible.

4. Determine Special Requirements

Some end users will have a need for a special requirement such as a one side cling, UVI or colored film. Reinforced film or vented film is also available. A one side cling is commonly used for bundling or on a pallet load that may shift in transit. Products that are stored outside for long periods of time normally require a UVI (Ultra-Violet Inhibitor) film. Heavy tinted colored films are often used to mask the product being wrapped for security reasons or for color-coding in large warehouses.

5. Determine Shipping Distance

The distance and method of shipment are important considerations. Films being transferred across the country in a flat bed truck or by rail would require a different film than a product shipped a short distance by truck or inter-plant. Your warehouse set-up might ship both ways and could need two different films. To help keep inventory on packaging products down it is important to discuss this when testing different films.