Top Packaging Trends for 2024

The business of industrial packaging doesn’t always give us the chance to celebrate the more colorful, fun side to consumer packaging. But, with the start of the year it is that time we highlight some of the best packaging trends we are seeing across the consumer industry and showing you how it can translate to the industrial world.

Smart Packaging

Sound familiar? It should – smart packaging has been around for quite a while with amazing innovations continuously coming to market. We’re not just talking about interactive QR codes or RFID tags for tracking in logistics. Smart packaging has grown substantially across industrial and consumer applications including moisture control, time-temperature indicators, and immersive technologies like AI and virtual reality.

How to incorporate in the industrial space: database-driven multi-line marking and coding offers superior quality and does not come with the service contract headaches you might be used to. Alternatively, labels and custom printed boxes can be a great addition to add smart packaging to your industrial line.

Anti-Theft Packaging

Anti-theft packaging isn’t new, but with its combination with smart packaging manufacturers are fighting back against in-store theft, porch pirates, and even theft at the plant. Reinforced water-activated tape is the most popular for in-transit shipments before they hit someone’s door, but things like black shrink film and plain packaging options for e-commerce deliveries are becoming popular again to fight porch pirates. Locking tab boxes, clamshells, and skin packers can all help anti-theft measures at the plant and in-store on the shelves.

Biodegradable Packaging

The continuous growing trend of biodegradable packaging is everywhere. As we have deeper conversations with customers and manufacturers it is important to note the industry has a long way to go until there are truly biodegradable packaging options in the marketplace. As consumers demand change, customers and manufacturers are teaming up to deliver solutions getting us closer to truly biodegradable options. If you are in the market for this type of product there are some key questions you should be asking the manufacturer before assuming the non-regulated term “biodegradable” is matching your expectations:

- What environment does the packaging need to be in to biodegrade (and is that environment available to your end user)?

- Is there a trusted third party certification the manufacturer can present? What does that certification say – will it fully degrade or partially degrade? In what timeframe?

- What materials are being used to make the packaging and what does that sustainability stream look like? Are the raw materials being sourced sustainably?

Sometimes the best answer is finding curbside recyclable and reusable packaging that your end users can easily handle across different states / local municipalities. Another answer could be to use more efficient packaging which is inherently more sustainable by nature!

The Packaging We Want to See Graveside as Consumers:

We all know we get packages in the mail that we just say – but why? Some of those answers while working in fulfillment are easier than others. But, we can all appreciate a little chuckle over silly frustrations whether our company is committing them or not – here are ours!

Mailer bags without a tear strip for easy opening: For the everyday consumer it is like the best invention since sliced bread. The convenience is an easy slam dunk!

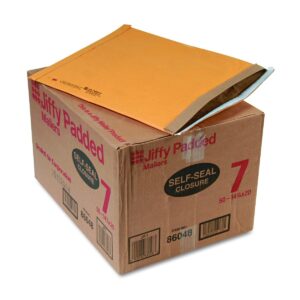

Small items in over-sized cartons: Give us a small padded mailer and call it a day – it helps with shipping costs and lowers our trash on collection days. Right-sizing is better for everyone!

Food packaging with ziplocks that rip the bag or without the little quick open notch: We love a good reusable food bag, but when that pesky ziplock feels more like a glue lock it can sadly rip that bag and make it harder to close. No more glue lock ziplocks!

Tough packaging for kids toys – whether it is sharp edged clamshells without easy open tabs with a smooth edge or a significant amount of twist-ties that can cause choking hazards – it’s hard being a parent with an excited child jumping on top of you trying to open and keep track of little packaging pieces.

and finally….

What We Are Looking Forward to in 2024 – Vendor Highlight

Paragon Films has been working hard on creating a stretch film with greater percentages of PCR – post consumer recycled content. With patents in hand they are the only stretch film on the market truly living up to the more modern take on sustainability goals delivering 25% PCR in the new Power Edge PCR Hand Stretch Film. This film focuses on the PCR content while continuing the trend of modern stretch film technology with a thinner gauge film. This film is a true game-changer when it comes to sustainability goals.

Paragon Films has been working hard on creating a stretch film with greater percentages of PCR – post consumer recycled content. With patents in hand they are the only stretch film on the market truly living up to the more modern take on sustainability goals delivering 25% PCR in the new Power Edge PCR Hand Stretch Film. This film focuses on the PCR content while continuing the trend of modern stretch film technology with a thinner gauge film. This film is a true game-changer when it comes to sustainability goals.

Paragon is removing used stretch film from the waste stream and putting it back into new usable film. Paragon estimates 1.5 billion tons of stretch film was produced in North America in 2020 with only a 16% recycled rate – only 1% being recycled into stretch film. Their goal is to increase both of those percentages while delivering a superior stretch film. Interested in learning if this film would be a good fit for your packaging line? Contact us!