Benefits of Package Converting

What To Expect

We pride ourselves in offering in-house and on demand converting for packaging converting department which helps customers looking for smaller order minimums, specialty size requests, and quick turnarounds. We’re happy to accommodate small to large projects based on the end user specifications – leading to greater flexibility overall.

Our on demand converting for packaging lets you receive precisely what you need without unnecessary waste or excess inventory. Whether you require unique dimensions, custom materials, or rapid production cycles, our team works closely with you to streamline the package converting process. This results in cost savings, improved efficiency, and a specific solution that meets the demands of your industry.

With our on demand converting for packaging capabilities, you gain access to high-quality materials, expert service, and a commitment to sustainability. Our converting process allows for better resource utilization, reduced waste, and optimized supply chain logistics. Additionally, with our in-house expertise, you can expect faster response times so that your packaging adapts quickly to the changing market demands.

What We Offer

Cutting

Sheeting

Slitting

Die Cutting

Label Printing

Kitting

Hole Punching

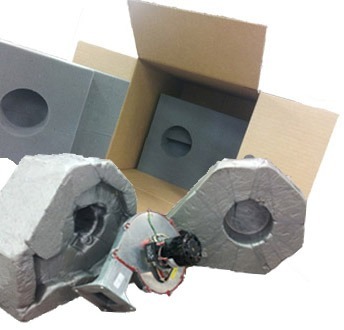

Foam-In-Place

Additional Services: Shrink wrap bundling or kitting for master cases to smaller retail packs, rewinding for smaller rolls or to add lining material – also available for VCI materials, woven material, foil, various tapes, etc.

On Demand Converting Project Highlights

Specialized Die-Cut Bee Boxes

Foam-In-Place Kitted Pieces

Customized Kitting

Custom Slit 2" Bubble Mask

On-Demand Barcode Labels

Desiccant Pack Kitting

Reach Out for On Demand Converting for Packaging

Colony Packaging gets it. Packaging isn’t one-size-fits-all, and businesses need options that actually fit their production cycles, storage capacity, and customer demands. That’s why package conversion is a way to keep operations flexible without unnecessary waste or delays. Whether it’s protective packaging, specialty coatings, or custom cuts, the right adjustments make all the difference.

Stock minimums shouldn’t slow you down. Neither should lead times that stretch longer than they should. On demand converting for packaging makes sure you get exactly what’s needed, when it’s needed, without waiting on massive production runs. Businesses experimenting with new designs or adjusting for seasonal shifts don’t have time for guesswork. This process keeps things lean & efficient.

Looking for an industrial packaging supplier that makes packaging work for you instead of the other way around? That’s where we come in. Let’s talk about what you need, whether it’s a custom run or a faster turnaround.